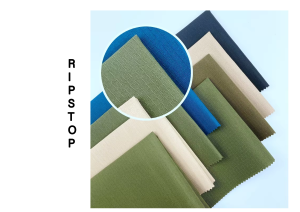

Every garment starts with the fabric. Choosing the right fabric is the foundation of good clothing, whether it’s breathable cotton, durable denim, or performance-ready sportswear textiles. The quality, texture, and durability of the fabric determine how the final product will look, feel, and last. At URBO, fabrics are carefully sourced and tested to ensure they meet both comfort and style standards.

Designing the Blueprint

Once the fabric is selected, the design process begins. This stage combines creativity and precision. Designers translate ideas into patterns that balance fashion trends with customer needs. Whether it’s a formal suit or a casual T-shirt, the design must capture the essence of the brand while staying practical for everyday wear.

Cutting and Preparation

With the patterns ready, the next step is cutting. Skilled professionals use advanced tools and techniques to ensure accuracy, minimizing fabric waste while maintaining consistency. Every piece is cut to fit perfectly into the larger puzzle that becomes the final garment.

Sewing and Stitching

This is where craftsmanship truly comes alive. Tailors and machine operators sew the cut pieces together, adding details like buttons, collars, zippers, and embroidery. At this stage, precision is everything. Flawless stitching ensures not only the garment’s durability but also its comfort and style.

Quality Check and Finishing Touches

Before reaching customers, every garment undergoes strict quality control. From checking seams to testing fabric color stability, each piece must meet high standards. Final touches like ironing, labeling, and packaging complete the journey, preparing the garment to leave the factory and enter wardrobes.

Bottom Line

The journey of a garment is more than just production; it’s a story of fabric, design, craftsmanship, and quality assurance. At Urbo, every step is handled with care to ensure that what starts as raw fabric ends as a fashion piece that customers are proud to wear.